Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: A25Ex-V

Brand: Calstar

Brand: Calstar

Texture Of Material: 304 Stainless Steel

Time Per Cycl: 3~4Hr

Socket Power: 220/50ACV/HZ

Dimension: 1124*730*1256 Mm

Weight: 144kg

Packaging: Wooden box

Productivity: 500set

Transportation: Ocean

Place of Origin: Shenzhen, China

Supply Ability: 10 sets per day

Certificate: ISO14000,ISO9001,Ex,CE

Port: Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB

Automatic Solvent Recovery Machine in New York

A25Ex-V Solvent Recycling Machine

A25Ex-V, high-end special equipment made for organic solvent recovery, automatic cycle operation, built in pneumatic automatic feeding device and vaccum pressure device, air-cooled condensing system, stationary and safe structure, is manufactured according to Chinese explosion-proof standards (CNEX) and European standards (ATEX). By distillation and cooling, clean organic solvents are recycled for use.

It is suitable for a small amount of organic solvent to recycle.

After waiting few hours, waste solvent has been reclaimed and you will get clean solvent to use!Solvent Recovery Machine application,Full automatic recovery machine,Working time of solvent recovery machine.

Customer Benefits

●High quality solvent recovery: clear, pure, good performance;

●Low maintenance cost, easy to maintain;

●Easy operation and installation: recovery process and operation is simple, convenient. General staff can secure posts after short-term training;

●The equipment is compact, small and light, space saving;

●24-hour automatic cycle operation, saves energy and cost of labor;

●Short process time and short operation time;

●Less investment, pay back quickly on investment; well-preserved environment and high economic benefits with less investment.Solvent recovery machine application,Full automatic recovery machine,Working time of solvent recovery machine.

Characteristic

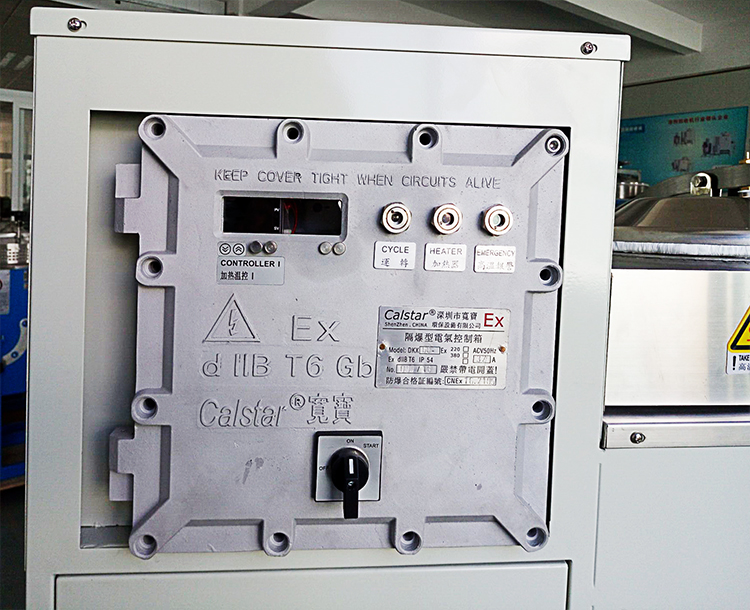

●Explosion-proof electric equipment: in compliance with Chinese safety standards (CNEX) and European standards (ATEX), worry-free and safe for use;

●Self-developed high-end standardized production, stable and durable quality assured, has good performance;

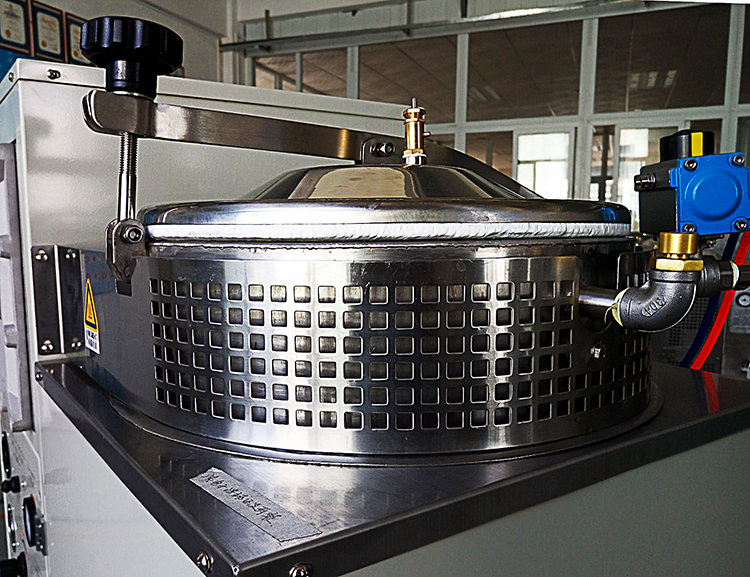

●High quality durable stainless steel tank, prevent chemical corrosion; two-tier structure, indirect heating, reinforcement barrelhead design, precise temperature control, explosion-proof, anti-leakage;

●Heating Method: heat medium (heat transfer oils) indirect heating;

●Digital heating temperature controller: advanced numerical performance, safety intuitive, accurate and convenient heating temperature control;

●Multiple operational safety protection functions: pre-set temperature shutdown function; timer shut off function; ultra-high temperature protection features; high-voltage protection function; power failure protection function.

●A 24-hour automatic cycle operation functions: a single cycle or continuous cycle operation, a 24-hour automatic cycle of operation.

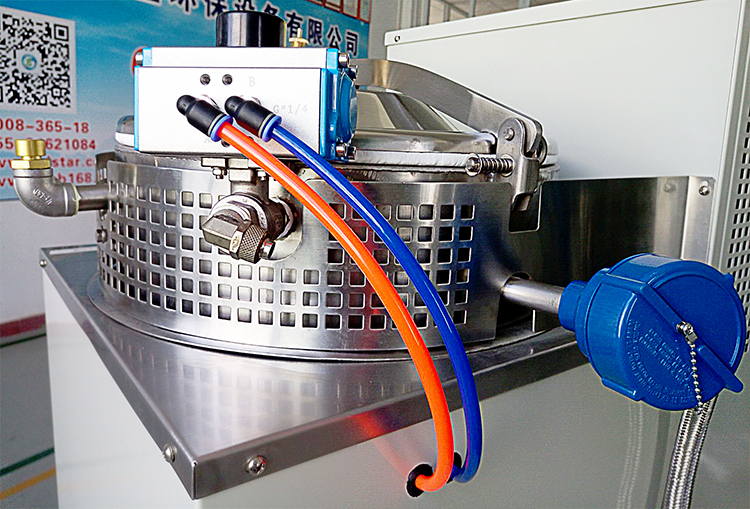

●Vacuum decompression recovery features: built-in vacuum (pump) devices, heating, condensation, vacuum, storage features and variety of functions in one machine; heating temperature is low, saving heating electricity; sealed recycling, reduces evaporation, prevents leakage; right volatility and easy to decompose, toxic or high boiling point solvent recovery with excellent effect.

●Automatic feeding and automatic cleaning residue functions: automatic or manual control feeding, without opening the cover feeding; cleaning of residue without need to open the lid, after recovery emptying is done by air pressure, high efficiency, low solvent evaporation, saves energy and cost of labor.

Customizing & Auxiliary device:

※You are free to customize the equipment to meet your specific needs, or choose auxiliary device in compliance with your needs in order to achieve the desired treatment effect.

Technical Parameters:

(for reference, the data subject to change, please with your choice models the actual date)

| Model | Feeding | Socket | Heating | Time | Compressor | Dimension | Weight |

| A25Ex-V | 25L | 220/50ACV/HZ | 50~190°C | 1.5~2Hr | 200L/min | 1124*730*1256 | 144kg |

NOTE: Values listed above, the recovery time is under ideal conditions in laboratory test values during recovery of toluene for reference. The actual operation in the process of recovery and the waste solution inside the impurity content, high and low boiling point solvents, environmental temperature, viscosity, etc. differ.Solvent recovery machine application,Full automatic recovery machine,Working time of solvent recovery machine.

Product Categories : Solvent Recovery Machine > Full Automatic Solvent Recovery Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.